SANFORD, N.C. — From Asheville to Durham to Wilmington, areas across North Carolina have looked at ways to discourage or even ban single-use plastic. In the new state budget, set to take effect soon, there is specific wording banning local governments from restricting auxiliary containers, including plastic cups or utensils.

Single-use plastics get a bad rap, environmentally, but their environmentally friendly alternatives can be quite expensive. That’s where a company that recently opened its first manufacturing facility in Sanford comes in.

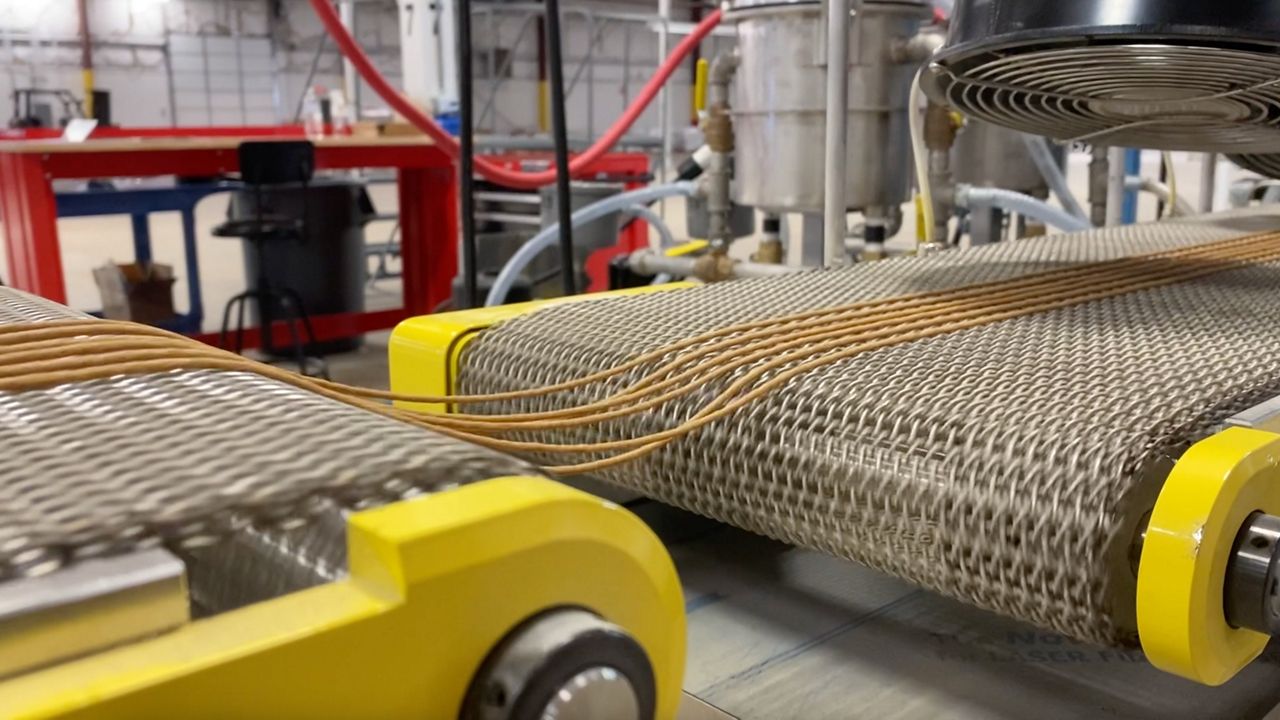

The company PlantSwitch buys leftover agriculture byproduct, including rice hulls, the husks on grains of rice. That byproduct is ground into a powder and made into small pellets. PlantSwitch sells those pellets to companies that want to make anything from straws to cosmetic packaging to forks.

Dillon Baxter, the 26-year-old CEO and co-founder of PlantSwitch, believes their product is a sustainability game-changer.

“The demand for products like this is overwhelming. I think the world is really understanding that you need to have a sustainable alternative to plastic,” Baxter said.

PlantSwitch’s Sanford warehouse was once home to a plastic manufacturer but, these days, it’s the exact opposite. PlantSwitch was started four years ago in Texas, and Sanford is now home to its first-ever manufacturing facility.

“We have what’s called a drop in solution. So instead of dropping in a plastic pellet, they’re using the same equipment, pretty similar conditions and just dropping in our pellet,” Baxter said.

The company’s plant-based plastic starts with agriculture byproduct, which typically goes unused. Baxter says over 100 million metric tons of that waste is produced every year.

Machines process the powder into strands, which cool on conveyor belts, and are then cut into tiny pellets.

“They will drop this into their equipment, melt it down, harden it, and then that turns into something like this, like a fork,” Baxter said.

Baxter says, unlike plastic, this material composts in a matter of months. He also says this kind of bioplastic does more than just preventing plastic pollution.

“We're giving waste a second life. We're helping solve that environmental issue. We're also providing another source of revenue to these farmers or agricultural producers and creating something that has a truly circular supply chain,” Baxter said. "Our goal is to use these renewable resources that are derived from waste streams and that allows us to have a truly sustainable alternative to something that you use on a daily basis across basically everything that you do.”

Baxter says they’ll be making at least 50 million pounds of their bioplastic pellets every year at their Sanford facility.

“We’re happy [with] and excited to bring a lot of jobs and make it the center of bioplastic production in the United States,” Baxter said.

PlantSwitch items are already carried by major food distributors like Sysco and U.S. Foods. Baxter also says they have a few exciting projects, with some pretty notable brands, on the horizon.

As for why they’re manufacturing in Sanford, Baxter says they were already looking at North Carolina, because it’s great for business and agriculture. Baxter says they have access to feedstocks and ocean ports, labor and a high quality of life.

PlantSwitch also received a $5 million USDA grant which allows them to support farmers who produce this agriculture byproduct, which includes underserved farmers in North Carolina and Virginia.

PlantSwitch plans to employ about 50 people at its Sanford facility.