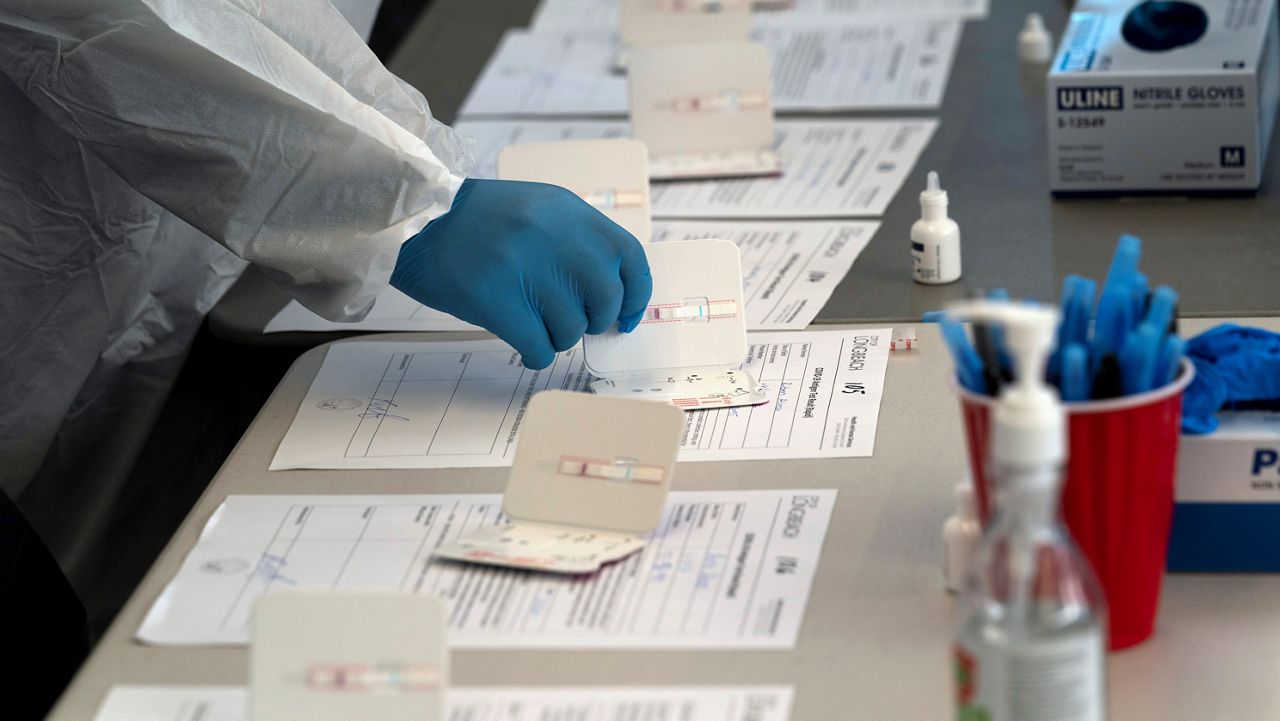

In the basement of Draper Hall at the downtown campus of the University at Albany, there is a 3D printer busy churning out protective equipment for COVID-19 frontline workers.

“We’re all working together remotely to find solutions and to find things that can actually help some of the people doing work in the field," said Michael Leczinsky, a professor in the College of Emergency Preparedness, Homeland Security, and Cybersecurity.

He says it takes about 40 minutes to print one of the medical face shields, which costs less than a dollar to make. As of Monday, 15 had been dropped off at Albany Medical Center.

“We’re looking to scale up so that we can start delivering hundreds of these units to Albany Medical Center, to Rensselaer County first responders, and throughout New York State,” Leczinsky said.

Over at the Electrical and Computer Engineering Department, faculty and students are also producing face shields. But their version is a little different and takes about three hours to make.

“This design has plastic that comes up to block any sort of splatter that might come over,” said Jonathan Muckell, a professor in the department.

He says this design has been approved by the National Institutes of Health. Muckell says about two dozen students are volunteering to supervise these printers, making supply runs, and assembling the face shields at home.

“The idea is we want these things running 24/7, just consistently because the 3D printing is the biggest bottleneck,” Muckell said.

These professors say access to more printers and supplies has helped make this possible as they continue produce as much protective equipment as possible.

CORONAVIRUS

UAlbany Makes Medical Face Shields For Frontline Workers

PUBLISHED March 31, 2020 @10:36 PM