MOORESVILLE, N.C. — The need for welders across our country is growing, all while industries like manufacturing and automotive fabrication are experiencing some worker shortages.

- Industries nationwide are in need of welders

- A new program on a Mooresville campus is helping to meet the welding need by training students to be experts in the field

- One of the Mooresville students is now preparing to start her first welding job in York, PA

From 2021 to 2031, The U.S. Bureau of Labor Statistics estimates employment of welders, cutters, solderers and braziers will grow at 2%, lagging behind the average for all occupations.

A new program in Mooresville aims to close the gap by getting more people in the North Carolina community trained so they can enter the job force as skilled welders.

In January, the Universal Technical Institute expanded its Welding Technology Training program to the NASCAR Technical Institute campus.

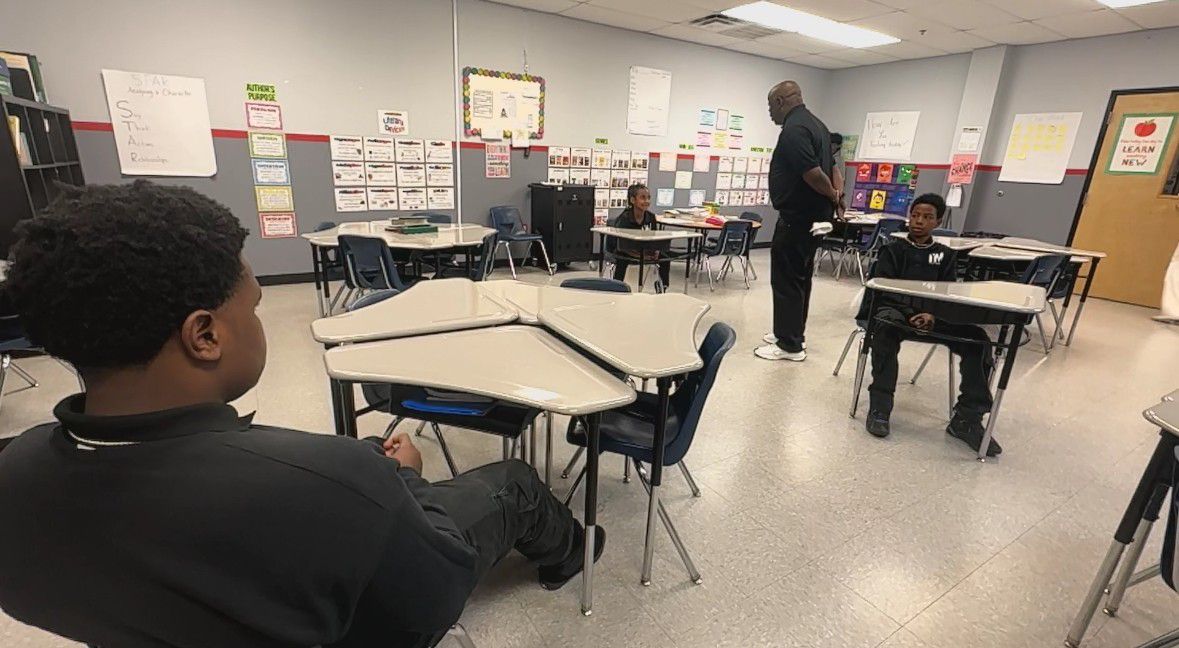

The 36-week training program gives students a hands-on experience so they know what it’s like working an actual welding job. Instructors who are experts in their welding professions lead the classes.

The curriculum consists of students training in welding booths and Lincoln Electric’s VRTEX virtual reality simulators, introducing them to tools found in their prospective careers.

Students will go through four processes to help them become welders:

- Gas metal arc welding

- Shielded metal arc welding

- Flux-cored welding

- Gas tungsten arc welding

Part of the coursework includes engineering and fabrication and pipe welding.

Mooresville just celebrated its first graduating class of welding students on Friday, Oct 7. Taylor Vacanti, 20, is one of the 12 graduates.

Vacanti is about to step into her professional welding shoes, after recently accepting a job with a large defense contractor in York, PA.

Staff at NASCAR Tech call Vacanti a standout student who excelled in the learning environment. But Vacanti says she didn’t always dream of becoming a welder.

After graduating from Mooresville High School, Vacanti says she pursued careers in the customer service field. But she says those jobs didn’t pay her enough money.

“I wanted a real job,” Vacanti said.

In January, she enrolled in the Welding Technology program at the NASCAR Technical Institute campus, hoping to one day land a higher paying job.

Vacanti says the program has been both enriching and rewarding.

“A lot of students who start out don’t know anything about [welding],” Vacanti said. “I didn’t know what welding was or how to do welding. This [program] was really helpful for me. It’s a lot of hard work.”

The need for welders like Vacanti in the state and across the country is in the thousands, according to the U.S. Bureau of Labor Statistics.

The organization’s most recent data says there are 428,000 people employed in welding occupations, but it’s not enough.

BLS is projecting around 47,600 openings for welders each year, on average, through 2031. They say many of the job vacancies are due to people retiring or workers leaving for a different occupation.

The American Welding Society echoes these shortage concerns. The organization is endorsing workforce data that projects nearly 150,000 people in the welding profession are approaching retirement, amplifying the need for more workers to fill those positions.

Instructors with the UTI Welding Technology program say the goal is to get qualified welders into those exact industries experiencing shortages.

Martin Ngigi is a welding instructor at NASCAR Tech.

Before taking on this role, he was a traveling welder for about 12 years, working in places like California, Florida, New Jersey and South Carolina.

Ngigi says the ongoing shortage of welders is concerning.

“A lot of people haven’t been in this industry. Many have been in banking, and [careers] like computer programming,” Ngigi said. “Industries like this [welding] have been lacking, but now we have people getting back into this industry.”

Ngig says the UTI Welding Technology program is critical with teaching students the ins and outs of welding, so they’re educated on the job demands.

“Welding is not just putting two pieces together and welding them,” Ngigi said. “It involves lots of things and preparation, there’s fabrication and the actual welding. All the instructors have been out in the field. This is not new to them. These students are getting firsthand what they should be expecting when they go out there. It’s not easy, it’s not for everybody.”

For students like Vacanti in search of a stable income, Ngigi says the pay in welding is good.

“There is money to be made, especially for traveling welders,” Vacanti said.

In May 2021, the median annual wage for welders, cutters, solderers and braziers was $47,010, according to the BLS.

Although Vacanti is excited about the welding pay, she says the big prize is entering a career she’s worked hard to get.

“Skys the limit,” Vacanti said.

Graduates of the welding program at NASCAR Tech will earn a diploma. The campus says the diploma could help students standout during their job search by showing they’ve received extensive training to work in the welding field.

NASCAR Tech says being educated on the welding profession will prepare students to enter numerous fields, including:

- Automotive maintenance and production

- Aerospace

- Manufacturing

- Railroad track repair and construction

- Farm machinery manufacturing

- Construction and infrastructure