According to a survey done by the New York State Cider Association (NYCA) in 2020, the hard cider industry contributed $1.7 billion in total economic impact, held 6,148 jobs, and generated $520 million in total wages for New York state workers.

Locally, one of the more popular cideries is 1911 in LaFayette. The head cider maker, Yann Fay, who has worked in this position for eight years, said in New York there are approximately 130 cideries when 25 years ago, there were only four or five.

“When I joined this company years ago, we had four people employed at the cider house,” said Fay. “I think now we're just under 20. Whether they're doing production or fermentation, or warehousing or shipping or marketing, there's a lot of jobs that we've added here.”

Fay believes that the popularity of cider increased with the younger generation’s willingness to try new things and it grew with the popularity of craft beer and the wine industry in the Finger Lakes region.

“Basically, no one knew what cider was 25 years ago, and now it's just under 2% of the beer market in New York state,” said Fay.

Steve Ammerman, director of communications at New York Farm Bureau, said the connection between New York’s apple production and hard cider makes the two flourish.

“It helps provide new markets for our apple growers,” said Ammerman. “It broadens the reach in the marketing efforts for New York apples at the same time, by having so many local producers, so many different varieties, that gives our cider producers more apples to play with, more flavor profiles.”

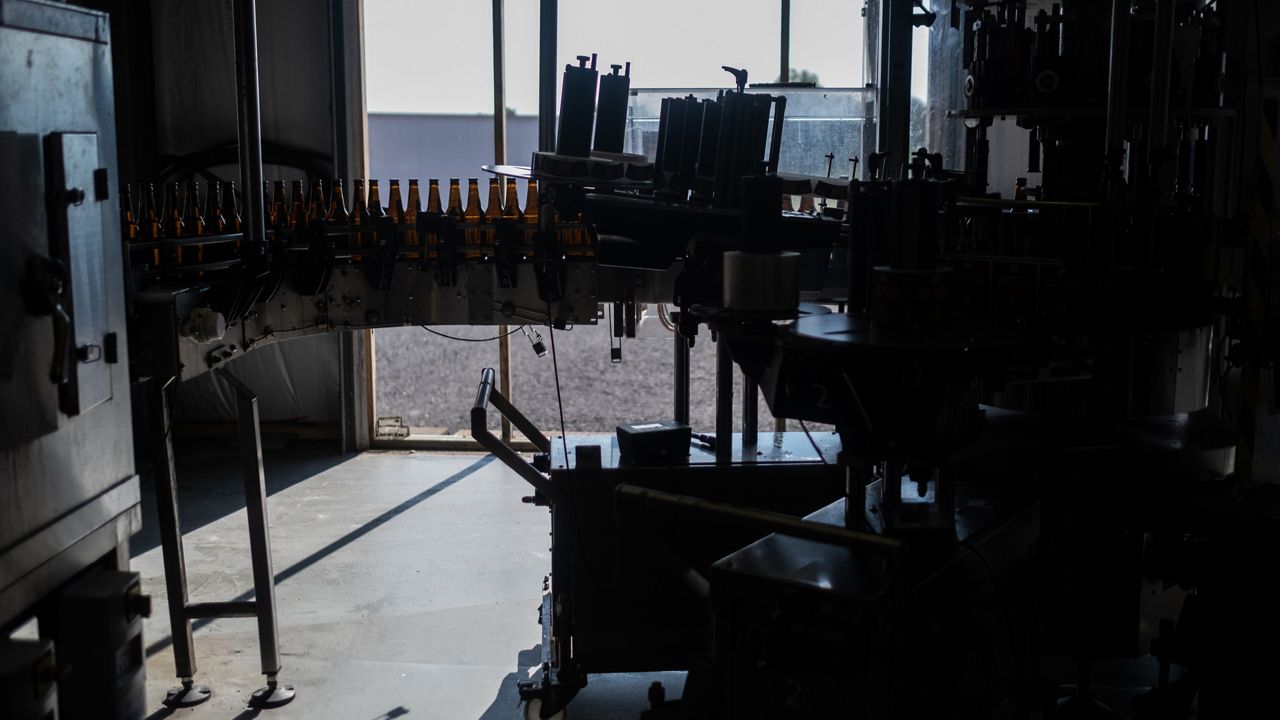

The process of making hard cider is an extensive process and requires a lot of hands, which allows Beak & Skiff to have a variety of different positions available.

While there are many jobs in the hard cider industry, the challenges of inflation and labor shortages impact orchards as well.

“They face a lot of other challenges like any other business right now, with inflationary pressures and the cost of labor, it's a concern for farmers in orchards right now, and just finding labor to prune the trees and to harvest the crops,” said Ammerman.

For 1911, the prices of supplies they need for packaging, such as cardboard, Saran wrap, and bottles and cans have increased. Additionally, they must purchase a certain amount for it to be delivered in bulk, Fay explains.

With the industry continuing to boom, The New York Farm Bureau is in the process of trying to pass state legislation that would allow for both in-state and out-of-state shipment of hard cider. It passed the state Senate this year, but not the Assembly.

“It would be one more market opportunity for our cider makers,” said Ammerman. “It would be greater access to customers, in particular, those out of state who may not find a large variety of New York hard cider in their local liquor stores or grocery stores.”

In the end though, the reward of working in the cider business for Fay is watching people enjoy the product.

“The best thing about working here is actually watching people buy the cider, drink it and have fun with it,” she said. “That's really where my pleasure comes from in the industry. It's just watching people have a cider with their friends, laugh and enjoy each other's company.”