DALLAS — The pandemic has opened a new perspective for many Texans when it comes to finding a happy work-life balance. Since June 2020 thousands of Americans have changed the direction of their career to seek out more fulfilling opportunities.

In North Texas, employees are feeling a strong sense of pride at a mask production facility that opened last August. With the delta variant keeping COVID-19 cases on the rise, masks are once again the new hot commodity in stores. Baylab USA is gearing up to start production around the clock to meet the spike in demand.

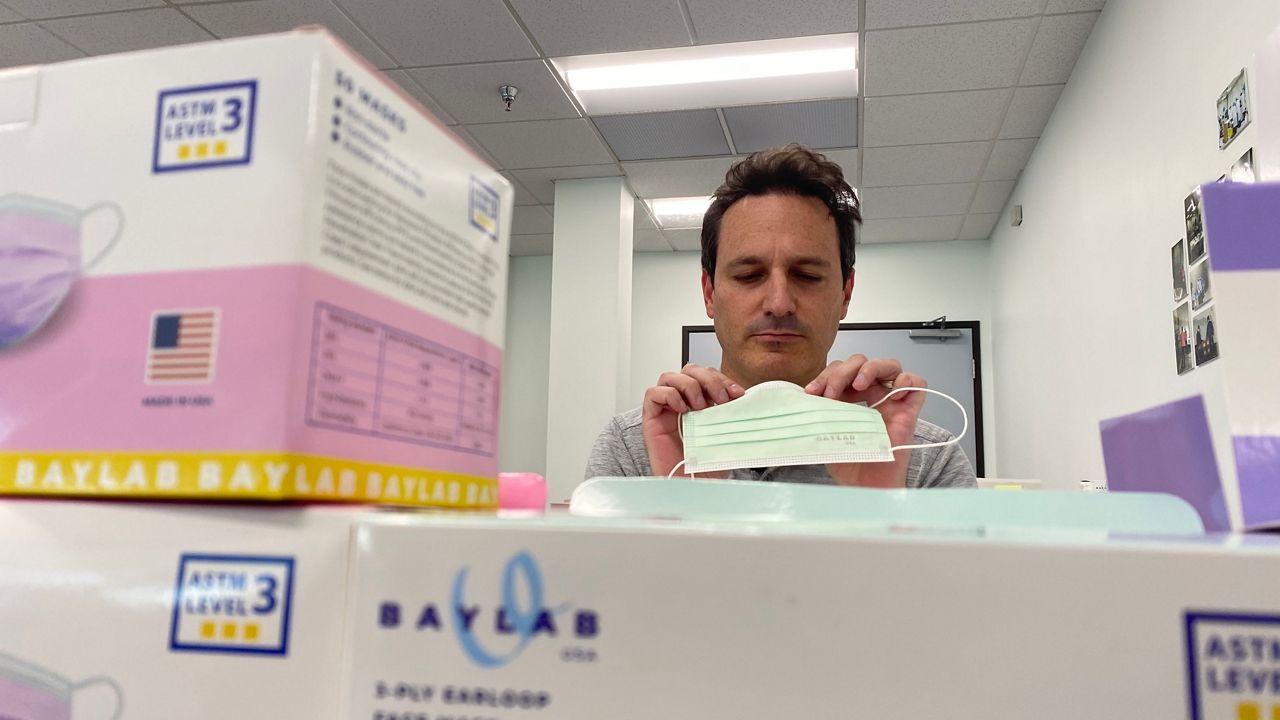

"It's very rewarding. It's something I never imagined I would find in a work-life," said Greg Bartell, of Baylab USA.

Bartell is tasked with overseeing the production line and ensuring employees are taken care of. Every shift he and dozens of others walk inside an ultra-clean warehouse to produce medical grade masks that are available to the community.

"It feels so much better getting up everyday knowing you're coming to a place where your products are in demand by medical and frontline dental personnel," said Bartell.

Just over a year ago Bartell had been working in a different role at a beverage facility in Dallas. Now with a pandemic to blame he's decided to take on a new opportunity.

"A lot of the basics are the same. You have people, you have materials, you have machines," said Bartell. "We're making products that actually protect people. Secondly, it's actually the dream of a start-up mentality. The Adrenaline that flows through this place is tremendous."

Many of the employees have left other jobs to work at the emergency mega start-up. Bartell says with COVID variants steadily putting a hamper on the community, the need for masks is crucial, as they continue to seek out more new hires.

CEO, Ashley Park, left her stable corporate career at Amazon after seeing the unique business opportunity within our border.

"When the research came in, it was costume designers making masks with cloth because we did not have enough surgical masks to provide our healthcare workers, and I couldn't wrap my head around it." said Park. "I didn't know what was going on."

A soar in international shipping costs on top of an onslaught of low grade masks being sold to the public made it easy for Park to make the decision to operate around the clock in the USA. She says with the COVID variants continuing to serve as an active threat, there will be a need to supply both the public, and our frontline medical workers.

"That's a key part of the business and honestly I would say it's been a rollercoaster for us all," said Parker. "I would say about five weeks ago is really when the light switch turned on again. It was the Delta. We sort of saw it coming in from Europe and India, and now we're hearing the Lamda variant is coming in too so we are forecasting that we need to be ramping up well into June 2022, so that we make sure we're stocked and hold inventory for those who need it."

Baylab USA says they've been able to source raw material from other US suppliers in order to keep costs down. More than 10 million medical grade masks and respirators are produced on a weekly basis at the warehouse.